D4-850-P0

Introduce

Break through the limitations of the existing configuration and realize the 2+2 axis serial-parallel hybrid connection with high speed and high performance. It has the features of translation along the XYZ axis and rotation around the Z axis. The installation methods are diverse and flexible, occupying a small space, and can be simply deployed in an automated production line.

Characteristic

1、With 2+2-DOF movement in three-dimensional space,robot can be used for more complicated handling operations

2、 The standard cycle time is less than 0.5s, meeting your pursuit for the maximum speed and the minimum volume.

3、Advanced design of transmission structure which combined with the advantages of series and parallel robots,enables the robot to easily cope with the high -intensity repetitive operation.

4、The robot is ideal for narrow space operations, as well ashigh-speed and high-precision in 3C field. Widely used inassembly, handling and testing of small work pieces.

Detailed product parameters

| Model | Axes | Payload | Manipulator | Repeatability | Rotation range | Allowable maximum moment of inertia | Angle range of actuated arm | Power supply | Power capacity | Rated Power | Storage temperature | Work environment | Protection | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D4-850-P0 | 2+2 | 5kg | Weight | Working space diameter | Position | Rotation | ±360º | 0.035kg·㎡ | ±147° | Three-phase 380VAC -10%~+10%, 49~61HZ | 4.25KVA | 1.8kw | -10℃~70℃ | -10℃~50℃,RH≤80% | IP55 |

| 58.6kg | 850mm | 0.05mm | 0.1º | ||||||||||||

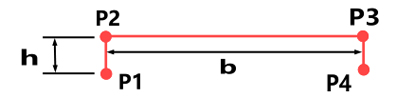

Load - frequency

| Name | Loop mode | Movement Distance |

|---|---|---|

| Trajectory1 | P1→P2→ P3→ P4 →P3 →P2 →P1 | h=25, b=305 |

| Trajectory2 | P1→P2→ P3→ P4 →P3 →P2 →P1 | h=25, b=500 |

| Trajectory3 | P1→P2→ P3→ P2 →P1 | h=25, b=305 |

| Trajectory4 | P1→P2→ P3→ P2 →P1 | h=25, b=500 |

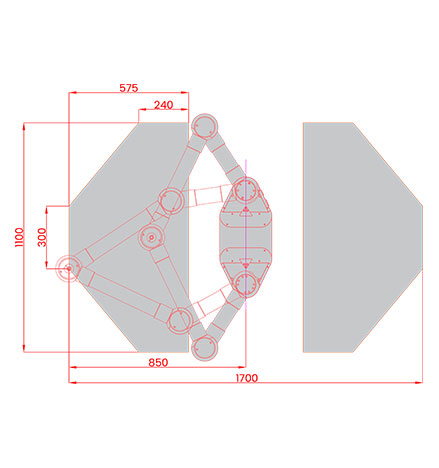

Drawing

-

01.Outline dimensions and Working range(mm)

-

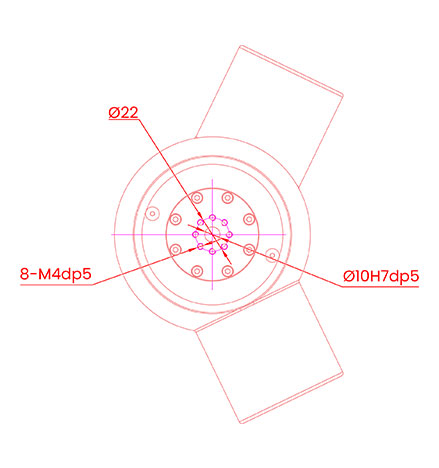

02. Flange(mm)

-

03.Base installation(mm)

.jpg)

.png)