Atomrobot Embeds at the 25th China International Industry Fair

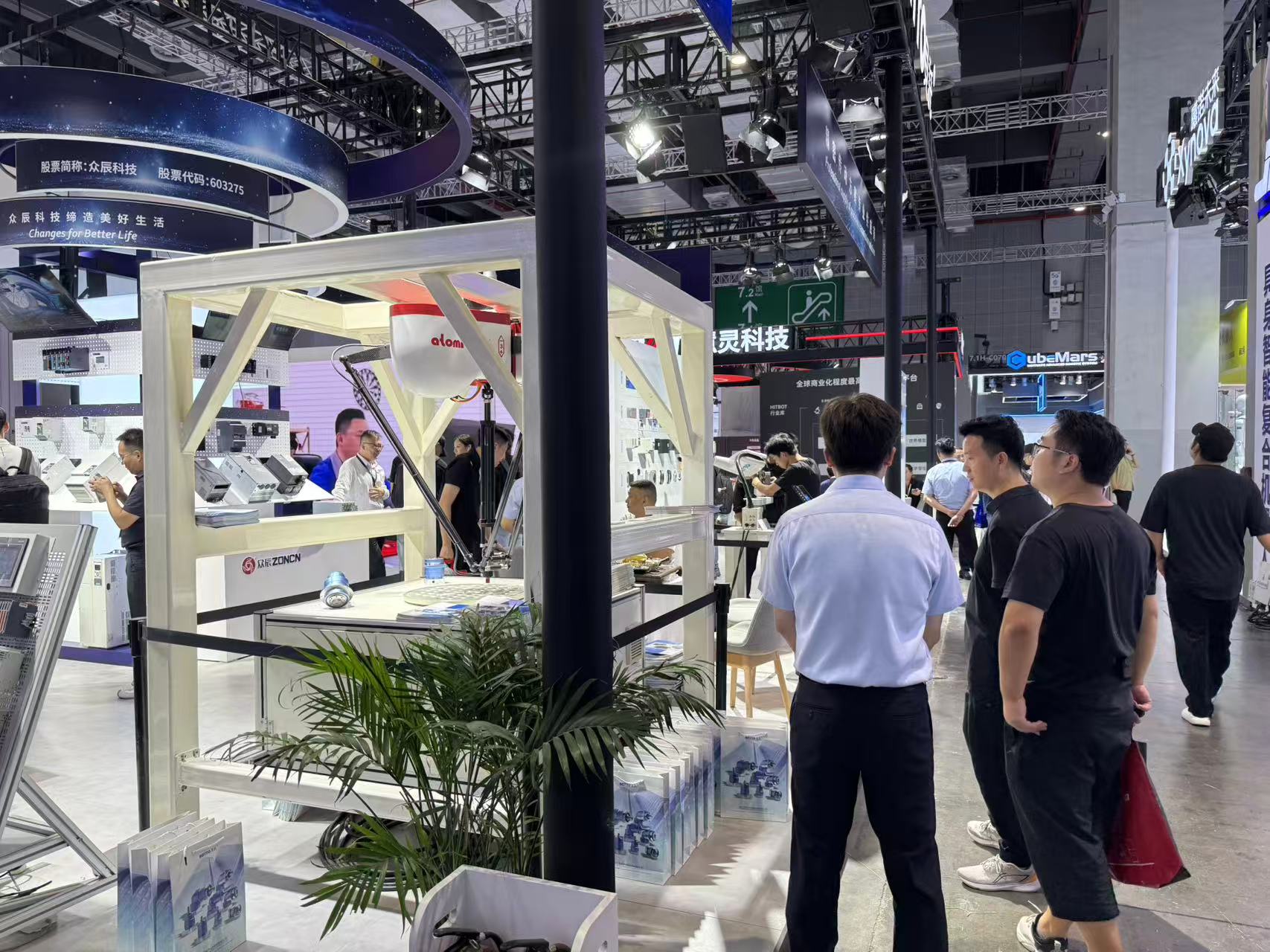

From September 23–27, the 25th China International Industry Fair (CIIF) grandly opened at the National Exhibition and Convention Center (Shanghai). At this year’s show, Atomrobot adopted an innovative “embedded” exhibition model, integrating three of its flagship products into the booths of core suppliers. Through dynamic demonstrations of real industrial scenarios, Atomrobot showcased its technological strength in high-speed and high-precision applications.

At the Hanwha Vacuum Technology (Wuxi) Co., Ltd. booth (No. 7.1-128), Atomrobot’s SCARA robot demonstrated high-speed and precise PCB handling, achieving repeatability of ±0.02mm. Alongside it, the Mini Delta Robot drew attention with a high-frequency sorting rate of 65 picks per minute. Meanwhile, at the Zhejiang Beito Transmission Technology Co., Ltd. booth (No. 7.1-196), the Disc Tracking Demo Unit highlighted the robot’s ability to perform accurate pick-and-place operations in dynamic environments.

Three Scenarios Highlighting Technical Capabilities, Tackling Industrial Challenges

Against the backdrop of rising efficiency demands in 3C electronics, semiconductors, and food packaging, Atomrobot’s three showcased models each provided innovative solutions to distinct industry pain points.

The SCARA robot, equipped with Hanwha’s vacuum gripping system, maintained ±0.02mm repeatability while achieving cycle times of under 0.36s (standard) / under 0.2s (high-speed), ensuring reliable handling of precision electronic components.

The Mini Delta Robot, with its lightweight arm design and optimized motion control algorithms, excelled in high-speed sorting scenarios, maintaining 65 stable picks per minute, meeting modern production lines’ stringent demands for efficiency and accuracy.

Most notably, the Disc Tracking Demo Unit at Beito’s booth simulated the complex conditions of continuous product flow on production lines. Through seamless integration of fast vision recognition and high-speed synchronous picking, the robot demonstrated precise operations in dynamic environments, underscoring Atomrobot’s deep expertise in motion control algorithms and trajectory planning.

Stable Supply Chain Ensures Reliability, Widely Validated by Industry As a leader in the high-speed industrial robotics sector, Atomrobot has built long-term strategic partnerships with core suppliers including Beito Transmission, Hanwha Vacuum, and leading Japanese manufacturers. This stable supply chain not only guarantees high-quality component sourcing but also ensures delivery reliability at scale.

“Beito precision reducers provide Atomrobot with accurate and reliable power transmission, ensuring stability and precision during high-speed tracking,” explained an Atomrobot product engineer. Such deep upstream-downstream integration has laid a solid foundation for achieving superior product performance.

Proven in the market, Atomrobot’s solutions have been widely applied across industries:

Food: High-speed sorting and packaging of mooncakes, candies, dairy products, and condiments.

Pharmaceuticals: High-speed and accurate medicine cartoning.

New energy: Sorting and arrangement of battery cells.

To date, over 8,000 Atomrobot systems have been deployed across industrial sites worldwide, with large-scale commercial success further confirming the products’ reliability and stability.

Innovative Exhibition Model: Mutual Empowerment Across the Value Chain

By appearing as an “embedded exhibitor” within its upstream suppliers’ booths, Atomrobot underscored its role as a flagship downstream partner. This innovative participation model not only showcased the integration of core components to complete robotic systems but also highlighted the mutual empowerment and win-win collaboration across the robotics value chain.

The 25th China International Industry Fair runs through September 27. Industry professionals are invited to visit Hall 7.1, Booth 128 (Hanwha Vacuum) and Booth 196 (Beito Transmission) to exchange insights and explore the innovative applications and future potential of industrial robots in smart manufacturing.