After Cobot palletizer Sales Tripled, This Company Unveils a New Move

According to data from GGII (Gaogong Industry Research Institute), in 2024, nearly 95% of China’s industrial robots were applied in operations such as palletizing & handling, welding, painting, assembly, and polishing. Among them, palletizing and loading/unloading robots accounted for the largest share—more than half of the market.

In this highly competitive “red ocean” of palletizing, Atomrobot is emerging as a strong contender.

Starting from high-speed parallel robots and gradually expanding into SCARA, Atomrobot is now leveraging its deep expertise in motion control and high-speed, high-precision applications to make a differentiated breakthrough into the palletizing market.

“With the incremental growth of the market, new business opportunities are constantly emerging. For palletizing applications, the demand for more adaptable and customized solutions is becoming increasingly urgent.”

Since the launch of Atomrobot’s cobot palletizer, the market response has been strong, with shipments growing threefold year over year. Shi revealed that by 2025, shipments of Atomrobot’s palletizing robots are expected to surpass its parallel robots.

From Fixed to Mobile: Breaking the Boundaries of Palletizing

As customer demand for flexible palletizing grows, traditional fixed palletizing stations—restricted to a single location—struggle to meet cross-point, cross-process, or cross-line needs in large warehouses or multi-area production facilities. This often forces companies to purchase multiple sets of equipment, driving up costs and consuming valuable floor space.

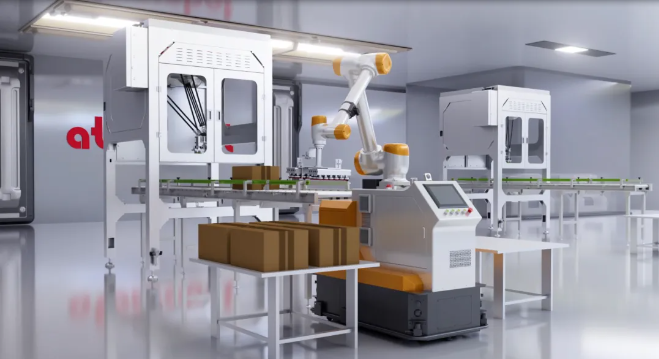

To address this challenge, Atomrobot has introduced its Mobile cobot palletizer—designed to solve the problems of “cross-point, cross-process, and cross-line” palletizing.

Mobile Collaborative Palletizing Workstation:

The Multiplier Effect of Mobility × Collaboration × Intelligence

Building on years of R&D in high-speed parallel robots and core technologies such as motion control, integrated drive-control systems, lightweight design, vision, and software toolkits, Atomrobot’s mobile solution delivers a mobility × collaboration × intelligence multiplier effect for the palletizing industry.

- Mobility:

- Collaboration:

- Intelligence:

Each mobile unit can cover 200–1000㎡, including multi-floor facilities, expanding its coverage area 5–20 times compared to traditional fixed systems.

Smarter Utilization, Lower Costs

For example, in a factory with 4–5 production lines operating below full capacity, traditional deployment would require one fixed palletizer per line—a total of 4 units. However, utilization rates are often low: one food company reported an average utilization of just 55% per fixed palletizer, with off-season idle rates exceeding 60% and annual waste costs surpassing ¥3 million.

With mobile collaborative palletizers, only 2 units are needed—each flexibly serving two lines. After completing tasks on Line A, the robot can automatically move to Line B to continue work, boosting equipment utilization to 85% and increasing overall efficiency by over 30%.

Currently, Atomrobot’s mobile collaborative palletizing workstations are being applied across industries such as food & beverage, pharmaceuticals, e-commerce, semiconductors, and 3C electronics.

Continuous R&D: Turning the “1% Spark” into a Wildfire

By 2024, the Chinese palletizing robot market reached a scale of ¥31.52 billion, a 16.8% year-on-year increase. This strong growth reflects the rising adoption of palletizing robots in industrial production and highlights the industry’s vast potential.

But how can companies stand out in such a large market?

Atomrobot believes the answer lies in the “1% demand”—the niche needs often ignored by others due to their small scale, unique requirements, or fragmented customer base. By precisely addressing this 1%, it sparks a wildfire of growth, turning a small foothold into a massive market opportunity.

This “from 1% to N%” expansion logic is Atomrobot’s core strategy: turning a differentiated advantage into market leadership.

“At this stage of stock-market competition, only continuous innovation can transform that 1% edge into 100% market influence. For Atomrobot, R&D is not a cost, but an investment in the future.”

Looking ahead, Atomrobot will continue to expand its portfolio with higher payload and longer-reach collaborative robots to meet the growing demand in palletizing applications, delivering customized solutions across diverse industries and production scenarios.