Economic benefits

-

Production capacity

22000Cups/hour -

Manpower

2 -

Productivity improvement rate

22.2% -

Payback period

1.5Years

Production-line process

-

01

01Stable transportation and turning transition, modular design, temporary adjustment of line length and layout according to the site conditions, with the function of cup pouring elimination.

-

02

02Equal distance material management) is arranged into neat two-way equal distance materials. It has the function of automatic support supply and torque protection to ensure the safety of operators.

-

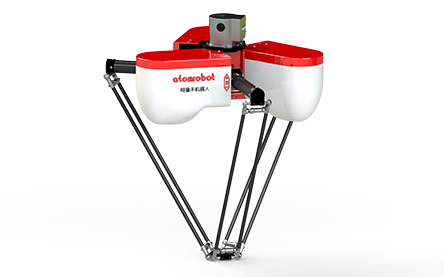

03

03atomrobot parallel robot picks and places materials, with a production capacity of 22000 cups / hour.

-

04

04After loading the milk, the plastic support is positioned at the intubation machine position, and the intubation machine completes push in intubation.

-

05

05Non equidistant pallet is sorted into equidistant output by differential handling. The end is connected with the heat sealing machine to replace the manual feeding line, which is brought in by the fork.

.png)

.png)

.png)